|

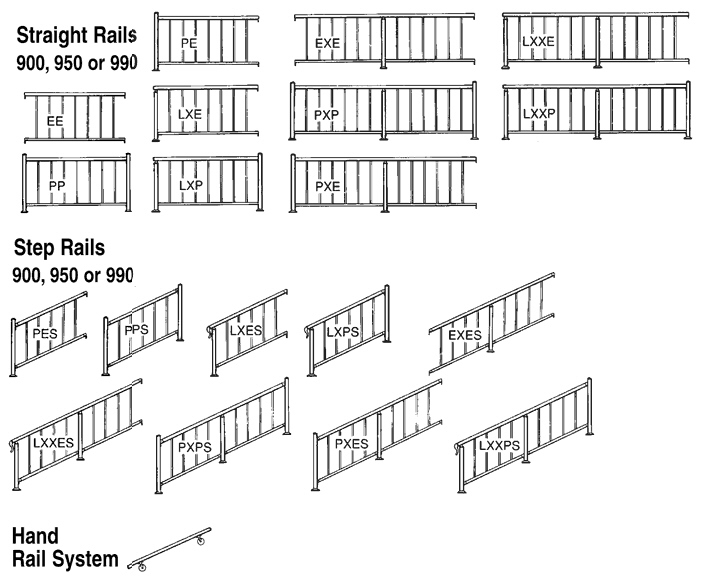

Heavy-Duty Aluminum Railing Series 900/9000

Suncoast Series 900 Heavy Duty Aluminum Railings offer the finest of

railing design features available on the market today. Highest quality

aluminum alloy extrusions are used to provide maximum strength and support

where it is needed most - in your installation. Series 9000 Heavy-Duty Railing features machined post openings on level and ramp railing, eliminating the need for brackets. The result is a clean, rigid design with added strength. If railing is angled horizontally, the angle must be specified so the proper openings can be machined into the post. Swivel brackets are required for step rail applications. The top rail has a 2” wide gripping surface which meets all safety criteria. The machined post openings and assembled sections (standard 6’ length or custom length) facilitate quick turn-around and overall savings to the customer.

|

||||

|

|

||||

|

Heavy-Duty Aluminum Railing Series 990 |

||||

|

|

||||

|

Materials All rails, posts and pickets shall be formed from 6063-T6 extruded aluminum alloys. All railing accessories shall be cast from ANSI 713 alloy. All exposed fasteners used in the system shall be aluminum or stainless steel. Series 900 railing meets federal safety requirements as determined by an independent testing laboratory. Test results available upon request. Suncoast Series 900 railing is protected by US Patent #3707276. Series 900 & 950 The railing system shall consist of 2" or 2-1/2" square posts that can be either base mounted, side mounted or embedded into concrete. The top rail shall be 2" or 2-1/2" wide and the bottom rail a minimum of 1-5/8" wide. Pickets shall be 3/4" square on 4-1/2" or 6" centers, and shall run between the top and bottom rail. The top rail shall be continuous in lengths up to 24'. The railing system will adapt to step railing requirements by specifying a rectangular hole in bottom rail. Series 990

The railing system shall consist of 2-1/2" square

posts that can be either base mounted, side mounted or embedded into

concrete. The top rail shall be 2" or 2-1/2" wide and the bottom

rail a minimum of 1-5/8" wide. Pickets shall be 1-1/2" x 3/4" on

5-1/4" or 6" centers, and shall run between the top and bottom rail.

The top rail shall be continuous in lengths up to 24'. The railing

system can meet step railing requirements by specifying the riser

and tread dimensions of the steps.

|

||||

|

Click here for "Photo Gallery" of Series 600 completed work

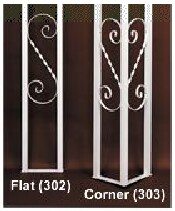

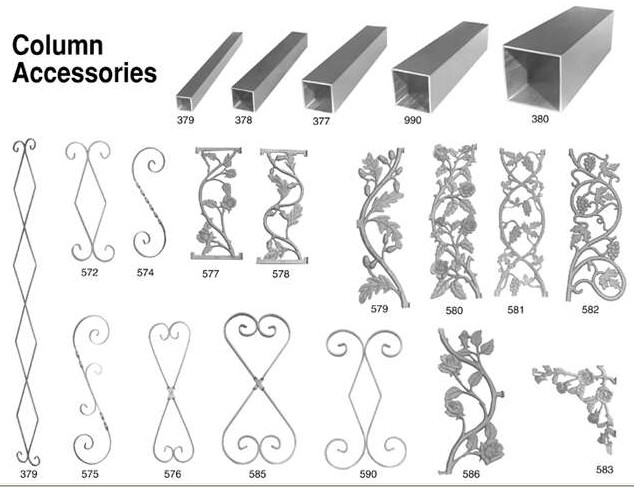

The Suncoast Series 600 custom railings offer a wide variety of designs and picket patterns to match the needs of residential or low rise, garden-type apartments. With all the advantages of aluminum – high-strength, durability, and rust free – their low lifetime costs makes them a good investment. Add a Suncoast Aluminum column, insert, or scroll for just the right detail.

The

Series 600 railings are available in heights from 32” to 42” and can be

purchased custom-made to your specs or K-D for assembly at the jobsite.

Five color choices with baked-on or anodized finishes ensure long lasting

beauty while the unique no-weld design allows for simple installation. All columns shown are available with 1" Square Extruded Tube by 8" wide overall and in 1-1/2" Square Extruded Tube by 9" wide overall. The 352/353 designs and 354/355 designs are available in 1-1/2" Square Extruded Tube by 12" wide overall. Also available with 2" or 2-1/2" square tubing.

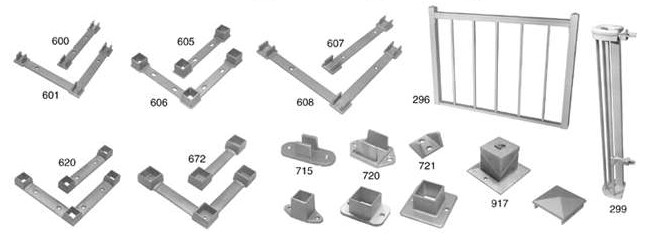

Standard columns are fabricated 8ft. high with top and bottom Materials All rails, posts and pickets shall be formed from 6063-T5 extruded aluminum alloys. All railing accessories shall be cast from ANSI 713 alloy. All exposed fasteners used in the system shall be aluminum or stainless steel. Series 600 Railing meets federal safety requirements as determined by an independent testing laboratory. Test results available upon request. Reg. Patent No. 3174727. Installation The railing system shall consist of 1-1/2" square posts that can be either base mounted or embedded into concrete. The top rail shall be a minimum of 1-1/2" wide and the bottom rail a minimum of 1-3/8" wide. Pickets shall be 1/2" square on approximately 6", 4", or 3" centers, and shall run between the top and bottom rail. The rail shall be continuous in lengths up to 16'. The railing system will adapt to step railing requirements by specifying a rectangular hole in bottom rail. |

||||

|

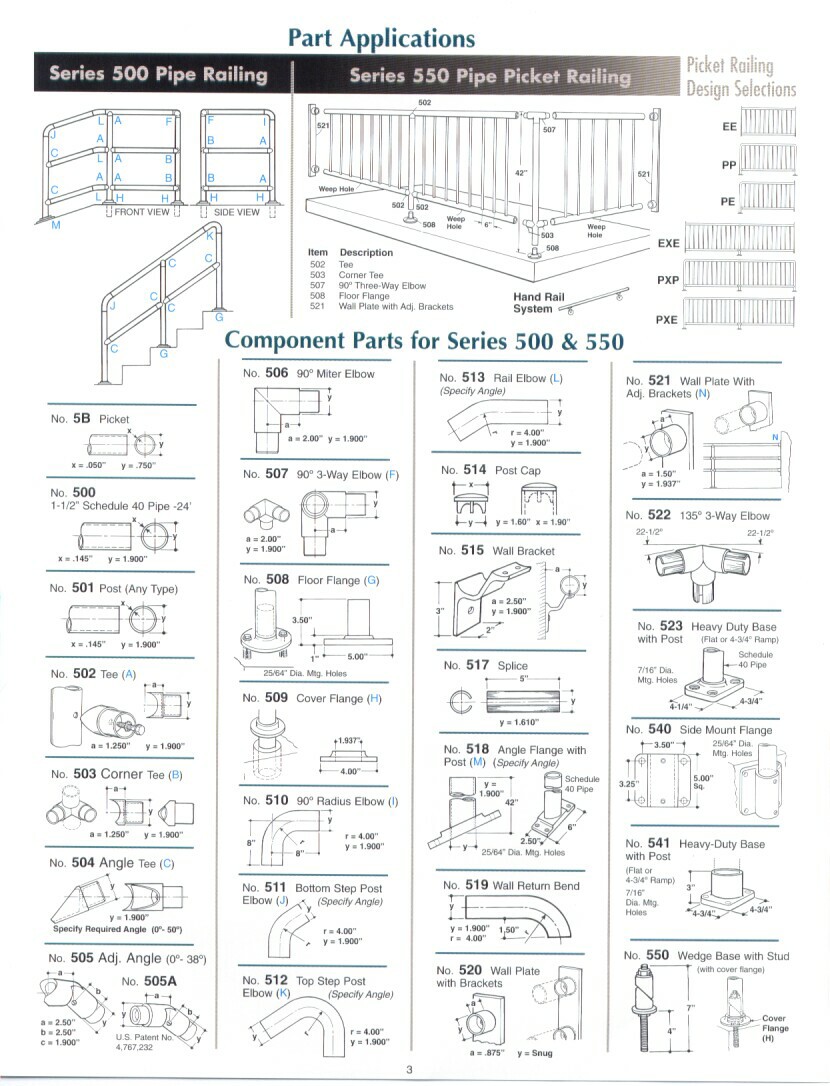

Heavy-Duty Aluminum Pipe Railing |

||||

|

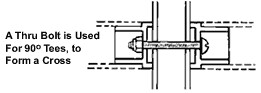

Post and top rails are assembled to run in continuous lengths, this results in a system that is stronger than one with a cast tee and cross connections and provides a continuous smooth top rail surface; pipe rail assemblies up to 24 feet can be shipped factory assembled or knocked down for reassembly. |

||||

|

Click here for "Photo Gallery" of Series

550

completed work

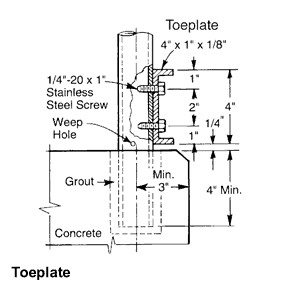

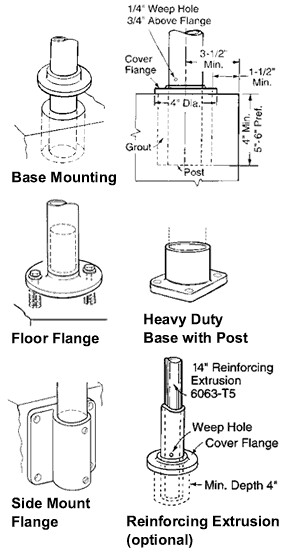

Materials All rails, posts and pickets shall be formed from 6063-T6 aluminum of 1-1/2 Schedule 40 pipe size, except where there are formed elbows, whereby, 6063-T4 is used. All railing accessories shall be cast from ANSI 713 alloy. All fasteners used in the system shall be aluminum or stainless steel. Workmanship All pipe cuts shall be square and accurate for minimum joint-gap. Cuts shall be clean and free of chamfer, from deburring, nicks and burrs. Holes shall be drilled the proper size for a tight flush fit of rivets and screws. All posts grouted in concrete must have one 1/4" diameter weep hole, 1/2" above post collar, in the plane of the rail. Rigidity Post spacing shall not exceed 6' 0" center-to-center. All posts will be a single unspliced length between posts. All top rails shall be continuous whenever possible. All fasteners shall be tightened so that completed railing is rigid and free of play at joints and component attachments. Scope of Work Suncoast Aluminum Series 500 railing meets federal safety requirements as determined by an independent testing laboratory. Test results available upon request. Technical Support For continuous spans in excess of 40 feet, expansion joints should be provided. To make an expansion joint, one end of the spliced joint should not have structural adhesive applied so that it is free to move in or out of the pipe. If a joint is provided every 30 feet, the width of the gap should allow 1/8" expansion for each 40OF of expected temperature rise. All pipe railing splices should be made no more than 12" from the nearest post. Materials All rails, posts and pickets shall be formed from 6063-T6 aluminum of 1-1/2 Schedule 40 pipe size, except where there are formed elbows, whereby, 6063-T4 is used. All railing accessories shall be cast from ANSI 713 alloy. All fasteners used in the system shall be aluminum or stainless steel. Workmanship All pipe cuts shall be square and accurate for minimum joint-gap. Cuts shall be clean and free of chamfer, from deburring, nicks and burrs. Holes shall be drilled the proper size for a tight flush fit of rivets and screws. All posts grouted in concrete must have one 1/4" diameter weep hole, 1/2" above post collar, in the plane of the rail. Rigidity Post spacing shall not exceed 6' 0" center-to-center. All posts will be a single unspliced length between posts. All top rails shall be continuous whenever possible. All fasteners shall be tightened so that completed railing is rigid and free of play at joints and component attachments. Scope of Work Suncoast Aluminum Series 500 railing meets federal safety requirements as determined by an independent testing laboratory. Test results available upon request. Technical Support For continuous spans in excess of 40 feet, expansion joints should be provided. To make an expansion joint, one end of the spliced joint should not have structural adhesive applied so that it is free to move in or out of the pipe. If a joint is provided every 30 feet, the width of the gap should allow 1/8" expansion for each 40OF of expected temperature rise. All pipe railing splices should be made no more than 12" from the nearest post. Durable maintenance-free pipe railing which is quick and easy to install without welding.

Railing splices are designed for a tight press fit and must be compressed with a pliers to permit them to slip into the pipe. The areas to be joined should be cleaned thoroughly. Mix adhesive according to manufacture's directions. Mix only enough that you can use within 1/2 hour. Apply adhesive to inside surface of pipe. Compress splice sleeve with a pliers, then slip into the pipe. Wipe off excess adhesive after components are properly joined. The areas connected together should be left undisturbed for eight hours, longer in cold weather. Tee Fittings

To attach the tee fitting to the post, a self tapping,

stainless steel, hexagon head screw with lock washer is

positioned through the fitting and threaded into the tubular

post. Mounting Options

|

||||

|

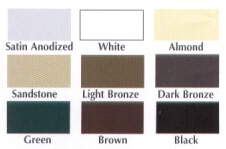

Finishes

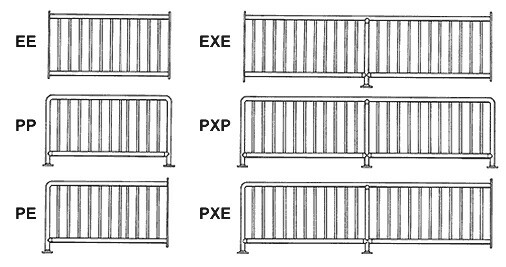

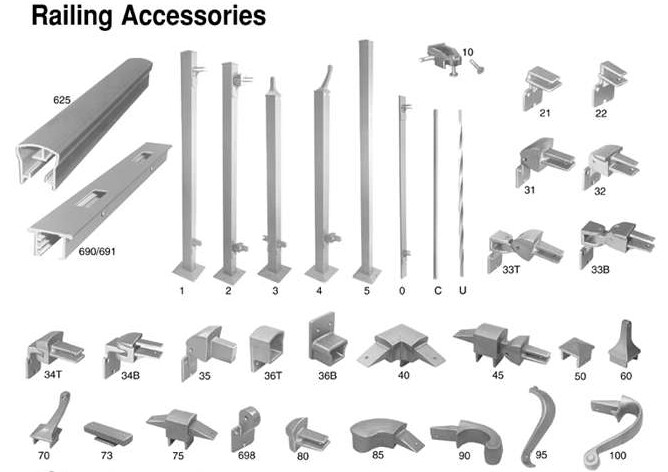

Typical Configurations |

Pipe

or picket railing can be embedded in concrete and grouted,

or mounted on decks and platforms with base flanges, or

side-mounted on fascia or stringer by means of fascia flanges.

Pipe

or picket railing can be embedded in concrete and grouted,

or mounted on decks and platforms with base flanges, or

side-mounted on fascia or stringer by means of fascia flanges.