|

Impact Windows

Suncoast recommends

Simonton and TRACO Impact Windows

Simonton

Do

you live in a home on the coast? Or, maybe you do construction work

on homes in a windy, coastal area? If so, you can now relax and

sleep a little easier. Do

you live in a home on the coast? Or, maybe you do construction work

on homes in a windy, coastal area? If so, you can now relax and

sleep a little easier.

Simonton Windows® has introduced

Simonton StormBreaker Plus™,

an impact resistant product line designed for high windborne coastal

areas. Double Hung Tilt, Casement, Awning, Geometric and Picture

style windows are all included in the new product line, plus an

impact resistant Garden Door (available with center hinge outswing).

Products in the Simonton

StormBreaker Plus line feature KeepSafe® Maximum glass.

The units are composed of a

piece of heavy polyvinyl butyral (PVB) plastic interlayer sandwiched between two pieces of double-strength glass. The

laminated glass is then combined with another piece of

double-strength tempered glass to form an insulating glass (IG)

unit. The IG unit, which has been sealed together to form a strong,

impact-resistant bond, is then glazed into the sash to hold the

glass in the frame. The glazing process from Simonton uses a

structural back bedding system to ensure the entire unit passes

impact tests and performs admirably in installed situations.

sandwiched between two pieces of double-strength glass. The

laminated glass is then combined with another piece of

double-strength tempered glass to form an insulating glass (IG)

unit. The IG unit, which has been sealed together to form a strong,

impact-resistant bond, is then glazed into the sash to hold the

glass in the frame. The glazing process from Simonton uses a

structural back bedding system to ensure the entire unit passes

impact tests and performs admirably in installed situations.

"Living

in a coastal areas with high winds can be a wonderful, yet sometimes

unsettling experience," says Bill Lazor, senior brand manager at

Simonton Windows. "Unexpected powerful storms can cause damage to

the home --- and windows are oftentimes most vulnerable. The new

Simonton StormBreaker Plus products can lessen concerns about the

exposure of the home to both storms and potential intruders. These

products have been proven to offer security and safety to the home." "Living

in a coastal areas with high winds can be a wonderful, yet sometimes

unsettling experience," says Bill Lazor, senior brand manager at

Simonton Windows. "Unexpected powerful storms can cause damage to

the home --- and windows are oftentimes most vulnerable. The new

Simonton StormBreaker Plus products can lessen concerns about the

exposure of the home to both storms and potential intruders. These

products have been proven to offer security and safety to the home."

Feel the strength of Simonton StormBreaker Plus products. When independently tested with air cannons, these windows didn’t just survive, they laughed in the face of the storm.

Think you’re hard on your windows? In the air cannon tests,

a two-by-four piece of lumber, nine-feet long, weighing nine pounds, was shot at specific and varying parts of the window unit at a rate of 50-feet per second. After the impacts, the units were then subjected to 9,000 cycles of combined positive and negative pressure. To pass the test, each unit subjected to these conditions needed to continue functioning. The glass had to stay intact in the sash and the Double Hung and Casement windows operationally. Strong and beautiful, Simonton StormBreaker Plus products are ideal for your coastal area home. a two-by-four piece of lumber, nine-feet long, weighing nine pounds, was shot at specific and varying parts of the window unit at a rate of 50-feet per second. After the impacts, the units were then subjected to 9,000 cycles of combined positive and negative pressure. To pass the test, each unit subjected to these conditions needed to continue functioning. The glass had to stay intact in the sash and the Double Hung and Casement windows operationally. Strong and beautiful, Simonton StormBreaker Plus products are ideal for your coastal area home.

The Simonton

Collection® includes a variety of product lines.

TRACO

TRACO Impact Resistant Window and Door Systems bring an expertise

and understanding of the unique needs of coastal area markets with

the right products, the right technology, and the right approach.

Specifically designed to meet strict building codes and the toughest

coastal weather challenges, TRACO Impact products are tested to

withstand the most severe hurricane force wind loads. High design

pressure windows and sliding-terrace doors goes beyond the

traditional benefits such energy-saving-performance by providing

added safety, security and peace-of-mind.

What is

impact glass?

Impact glass is a laminated glazing product, produced by bonding

a combination of plastic vinyl layers and polyester film between

two pains of glass into a single sheet. Laminated glass looks

like ordinary glass, but protects like a shield against

accidental impact, forced entry, sun damage and unwanted noise.

Tests show that specially designed laminated glass products pass

windborne debris impact tests, and when broken the glass

fragments tend to remain integral, adhering to the plastic

interlayer, helping to preserve the integrity of the building

envelope. Impact glass is provided in a Low-E configuration, but

it does not have an open space between the two glass panes.

What

does Low-E stand for and how does it benefit my project?

Low-E stands for low-emissivity, which is the power of a surface

to emit heat by radiation. This type of glass cuts the loss of

heat during the winter and cuts the absorption of heat during

the summer by reflecting the heat back to its source, thus

providing year-round savings by lowering utility bills. Low-E

glass also selectively filters the sun’s energy, blocking up to

84% of the sun’s ultraviolet rays in the summer, thereby

reducing the degree of fading of upholstery, carpet and drapes.

Low-E also reduces heating costs reflecting room side heat back

into the room with a resulting in a lower winter U-value.

What is

insulated glass?

Technically, there are two or more panes of glass separated by

insulation at the edges and air in the center to provide greater

thermal efficiency to a window.

What is

a gas-filled window?

Modern window technology permits an inert gas, usually argon, to

be sealed between the panes of glass in a window instead of air.

The gas is a far better insulator that just air, thus further

increasing the thermal value of a window.

What

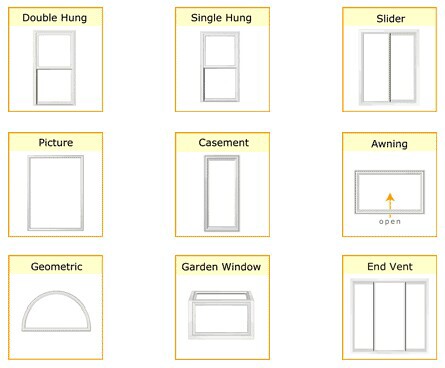

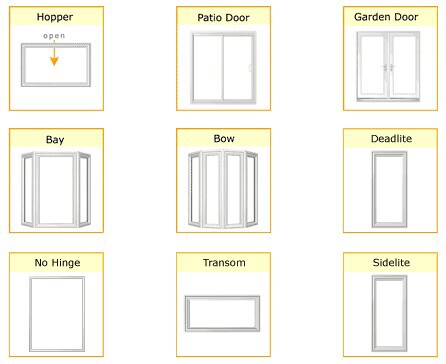

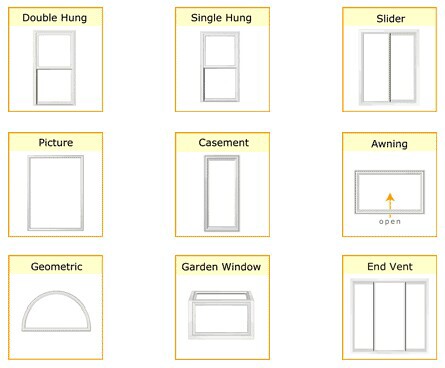

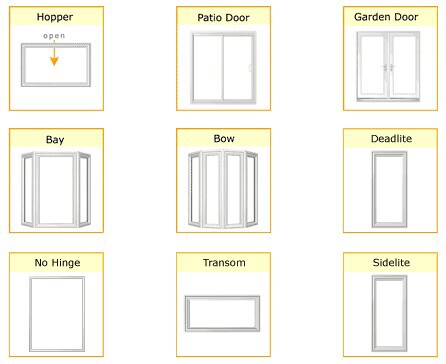

are some common styles of windows on the market today?

Depending on region and personal style, single-hung, double

hung, casement, awning, slide-by, bay and bow windows are the

most frequently used. A number of other style windows are

frequently employed as accent windows.

How

does a double hung window differ from a single hung window?

A double-hung window has two vertically moving sashes, each

opening and closing a different part of the window. While a

single hung window has only one moving sash, which is the bottom

portion of the window.

What

is a casement window?

A casement window is a window unit hinged at the side that

swings outward, operated by a cranking mechanism.

What

is an awning window?

An awning window is hinged at the top and swings out at the

bottom to open, operated by a cranking mechanism.

What

is a bay window?

A bay window is a series of usually three windows assembled in a

polygon shape that projects outward from the side of a house.

How

does this differ from a bow window?

Bow windows are very similar to bays, in that they also project

from the side of a house. However, they are usually composed of

a series of five window units assembled in an arc, rather than a

polygon.

You

mentioned that a number of special units are also available for

use either separately or in conjunction with the units above.

What are some of these units?

Many of these are special shapes. For example, they include

hexagonal windows, round windows, half and quarter-rounds (which

are exactly what the name implies), dormer windows, French

windows (two casement sash hinged together to allow them to be

opened into a confined space), lancet windows (tall narrow

windows with a pointed arch top frequently used in Gothic

architecture), and transoms, which are window units usually

located above a door.

What

are mullions?

Mullions are vertical members between window units. They are

sometimes confused with muntins, which are secondary framing

members that hold multiple panes of glass in the sash. Other

parts of the sash include stiles (the outside vertical members)

and rails (the top and bottom horizontal members).

I

have heard windows referred to as lights, is this another type

of window?

Lights (sometimes also spelled lites) are individual panes of

glass within a window. Windows are usually designed/measured by

the number of “lights” it has in each sash.

What

are jambs?

Jambs are framing members used to support the window in the

wall. Those framing members on the side are, logically enough,

called side jambs. The framing member at the top is a head jamb.

There are no jambs at the bottom. This framing member is

referred to as a sill.

There are many general terms that I hear quite often, but some

of them I do not understand. For example, what is a sash?

A sash, simply put, is the entire window, including the glass

and the surrounding pieces that hold it together. The sash fits

into a frame that is actually tied into the surrounding wall and

holds the sash in place.

Why do my new

insulated-glass windows "sweat" during cold weather?

Even the best-insulated

windows can condense moisture from the air if the outdoor

temperature is low enough and the indoor relative humidity is

high enough. You're probably using a room humidifier or a

humidification system connected with your furnace. Assuming that

the windows were properly installed, try reducing the humidity

setting during very cold weather.

Here are a few tips on

reducing the moist air in your home:

- Use fans in

bathrooms, kitchens and laundry rooms to circulate the air.

- Air out your home frequently by

opening doors and windows.

- Reduce the number of indoor

house plants, as plants increase humidity levels.

- Use a dehumidifier to remove

excess humidity from the air.

General Information

Configurations

-

Double

weather-stripping throughout.

-

Full

view or colonial muntins.

-

Forced-entry approved and burglar resistant.

-

All

stainless steel hinges. Heavy-duty operators and locks.

Materials

-

All

frames, vents and screen frames are manufactured of extruded

6063-T6 aluminum.

-

Frames

and vents are constructed using stainless steel corner keys.

-

Single

row plastic backed and shrink resistant. Applied to both frame

and vent.

-

Non

impact units are available with 3/16" and 1/4" thick glass

annealed or tempered.

-

Insulated units have 1/2" overall glass thickness.

-

Impact

resistant units use .125/.090/.125 annealed or heat treated

glass.

-

All

hardware is manufactured by Truth Hardware or equal, and come

with a 5 year limited warranty.

-

All

aluminum members will received an ESP finish.

-

Available with impact resistant glass, insulated glass, tempered

safety glass.

-

Standard colors are white, tan, bronze ESP and clear anodized,

custom colors available.

Performance

-

Design

pressure of positive and negative 85 psf (unit test size 48” x

120”)

-

No

water penetration at 15 psf of positive pressure

-

Air

infiltration = 0.050 cfm/sq. Ft. at a pressure differential of

6.24 psf

-

Tested

and passed Dade County Pa 201, 202, 203.

-

Original Dade County Acceptance No. 96-1024.02

-

Renewal Dade County acceptance No. 00-0524.003

Materials

-

ALUMINUM: 6063-t6 extruded aluminum frame members and 6063-t5

aluminum glazing beads. Minimum wall thickness for main framing

members to be .090 thickness and glazing beads .070 thickness

-

GLASS:

Uvekol glazing panel consisting of, outboard light of ¼” thick

glass with an interlayer .120 mil laminate and inboard light of

¼” thick glass.

Impact and

Cyclic Test Standards

|

SBCCI

SSTD 12

LARGE MISSILE IMPACT TEST:

Height and grade up to and including 30.0 feet.

-

Impact Option 1: Three

identical test specimens, each specimen is impacted

twice. One at the center and one within 6" (152mm)

of a corner.

-

Impact Option 2: Six test

specimens, each impacted once. Three specimens at

center, three specimens impacted within 6" (152 mm)

of a corner.

-

Options 1 and 2

consists of a 2" x 4" Timber.

-

Weight and speed of the 2" x 4" Timber specific

to wind speed:

90 < wind speed = 100 4lb. (2kg) missile

impacting at a speed of 40 ft. (12m)/sec

|

100 < wind speed = 1108 4lb. (4kg) missile

impacting at a speed of 40 ft. (12m)/sec

|

Wind speed = 110 9 lb. (4kg) missile

impacting at a speed of 50 ft. (12m)/sec

|

-

Impact Option 3-pendulum impact

apparatus. Refer to test standard for impact

criteria.

-

To past test no penetration is allowed in which

a 3" (76 mm) diameter sphere can pass. (Impact

Options 1-3)

-

The cyclic pressure loading test is not required

when at one ply of the impact glass product does not

beak during missile impact test and the material is

designed to withstand the design wind pressure. (Impact

Options 1-3)

|

|

SMALL MISSILE IMPACT TEST:

Height above 30 feet (9m).

-

Three identical test specimens.

-

Test is conducted with steel balls each weighing

2 grams and impacting at a speed between 130 ft. per

sec. and 132 ft. per sec.

-

Test consist of thirty small missile impacts:

110 at the center, 10 at the center/long dimension

side, 10 at the corner

-

The specimen passes the impact test if/when no

penetrations are created in which a 3" (76 mm)

diameter sphere can pass through.

-

All three specimens must pass prior to

proceeding to the cyclical pressure loading test.

NOTE:

The cyclic pressure loading test is not required

when at least one ply of the impacted glass make-up

does not fracture during missile impact test and the

ply is designed to withstand the design wind

pressure.

|

|

CYCLIC WIND PRESSURE LOADING

SFBC and SBCCI

Test specimens passing the large and small missile impact

test criteria move on to the cyclic wind pressure test.

Pmax: Denotes the maximum design load

allowed in accordance with ASCE 7-88. "Minimum Design Loads

for Buildings and Other Structures."

Pass/Fail Criteria

SFBC - Dade County Addition: A particular

system of construction shall be deemed to comply with this

recommended practice if three test specimens reject the

missile impacts without penetration and resist the cyclic

pressure loading with no cracks forming which are longer

than 5" and 1/16" wide through which air can pass.

SBCCI SSTD 12: The test specimens shall

resist the missile impacts prescribed and resist the

cyclical pressure loading with no cracks forming longer that

5" through which air can pass or with no opening through

which a 3" diameter sphere can pass. |

|

Do

you live in a home on the coast? Or, maybe you do construction work

on homes in a windy, coastal area? If so, you can now relax and

sleep a little easier.

Do

you live in a home on the coast? Or, maybe you do construction work

on homes in a windy, coastal area? If so, you can now relax and

sleep a little easier.  sandwiched between two pieces of double-strength glass. The

laminated glass is then combined with another piece of

double-strength tempered glass to form an insulating glass (IG)

unit. The IG unit, which has been sealed together to form a strong,

impact-resistant bond, is then glazed into the sash to hold the

glass in the frame. The glazing process from Simonton uses a

structural back bedding system to ensure the entire unit passes

impact tests and performs admirably in installed situations.

sandwiched between two pieces of double-strength glass. The

laminated glass is then combined with another piece of

double-strength tempered glass to form an insulating glass (IG)

unit. The IG unit, which has been sealed together to form a strong,

impact-resistant bond, is then glazed into the sash to hold the

glass in the frame. The glazing process from Simonton uses a

structural back bedding system to ensure the entire unit passes

impact tests and performs admirably in installed situations.

"Living

in a coastal areas with high winds can be a wonderful, yet sometimes

unsettling experience," says Bill Lazor, senior brand manager at

Simonton Windows. "Unexpected powerful storms can cause damage to

the home --- and windows are oftentimes most vulnerable. The new

Simonton StormBreaker Plus products can lessen concerns about the

exposure of the home to both storms and potential intruders. These

products have been proven to offer security and safety to the home."

"Living

in a coastal areas with high winds can be a wonderful, yet sometimes

unsettling experience," says Bill Lazor, senior brand manager at

Simonton Windows. "Unexpected powerful storms can cause damage to

the home --- and windows are oftentimes most vulnerable. The new

Simonton StormBreaker Plus products can lessen concerns about the

exposure of the home to both storms and potential intruders. These

products have been proven to offer security and safety to the home." a two-by-four piece of lumber, nine-feet long, weighing nine pounds, was shot at specific and varying parts of the window unit at a rate of 50-feet per second. After the impacts, the units were then subjected to 9,000 cycles of combined positive and negative pressure. To pass the test, each unit subjected to these conditions needed to continue functioning. The glass had to stay intact in the sash and the Double Hung and Casement windows operationally. Strong and beautiful, Simonton StormBreaker Plus products are ideal for your coastal area home.

a two-by-four piece of lumber, nine-feet long, weighing nine pounds, was shot at specific and varying parts of the window unit at a rate of 50-feet per second. After the impacts, the units were then subjected to 9,000 cycles of combined positive and negative pressure. To pass the test, each unit subjected to these conditions needed to continue functioning. The glass had to stay intact in the sash and the Double Hung and Casement windows operationally. Strong and beautiful, Simonton StormBreaker Plus products are ideal for your coastal area home.